Have you ever wondered about the secrets lurking behind the sturdy exterior walls of an RV? Well, get ready to have your curiosity satisfied as you can delve into the world of RV exterior wall thickness with this useful article. This often-overlooked element plays a crucial role in not only protecting you from the elements but also enhancing your overall RV experience. Whether you’re a seasoned RV enthusiast or a newbie embarking on your first adventure, understanding the thickness of your RV’s outer walls is essential. So, dive in and explore the fascinating world of RV exterior wall thickness together!

Table of Contents

Types of RV Wall Construction

Aluminum Frame with Fiberglass Exterior

This type of RV wall construction is composed of an aluminum frame with fiberglass exterior walls. These RVs are lightweight and fuel-efficient, making them a great choice for long trips. The aluminum frames provide superior structural strength while the fiberglass outer layers prevent damage from UV exposure and other environmental conditions. They also offer superb insulation, helping to keep the interior temperature comfortable in the summer and warm in the winter.

Wood Framed with Aluminum Siding

Wood framing with aluminum siding is a widely preferred choice for RV wall construction due to its exceptional durability and affordability. The combination of a sturdy wood frame and the added layer of protective aluminum siding ensures enhanced resistance against weathering, wear, and the test of time. This type of construction is ideal for those seeking a long-lasting and cost-effective solution, allowing for worry-free adventures on the road.

Laminated Composite Walls

Laminated composite walls are one of the most popular choices for RV wall construction today due to their strength and durability. This type of construction consists of layers of fiberglass, plywood, and aluminum bonded together with resins and adhesives. The result is a lightweight yet strong material that provides superior insulation, soundproofing, and UV protection. Furthermore, a unique manufacturing process ensures that laminated composite walls are highly resistant to corrosion and other external factors.

Foam Core Walls

Foam core walls are a great choice for lightweight RV wall construction due to their low weight and superior insulation properties. This type of construction consists of an aluminum frame filled with polyurethane foam insulation. This combination of materials creates a lightweight yet insulated wall that is highly resistant to water damage and provides excellent soundproofing. Additionally, the insulation properties of foam core walls help keep the interior comfortable in both hot and cold temperatures.

Steel Frame With Aluminum or Fiberglass Exterior

This type of RV wall construction utilizes a steel frame with an aluminum or fiberglass outer layer for superior protection against the elements. The steel frame offers exceptional strength and durability, while the aluminum or fiberglass exterior provides added insulation and resistance to UV exposure. This type of construction is often chosen by those seeking long-term investment in their RV due to its superior longevity and superior protection from the elements.

Solid Fiberglass

Solid fiberglass construction is another popular choice for RV wall construction. This type of construction consists of a single layer of reinforced fiberglass with no additional framing or insulation. The solid fiberglass material is lightweight, providing great fuel efficiency and easy maneuverability on the road. In addition, solid fiberglass walls are highly resistant to wear and tear due to their strength and durability. It is also extremely resistant to UV exposure and other environmental conditions, making it an ideal choice for outdoor adventurers seeking a long-lasting solution for their RV.

Hybrid Walls

Hybrid walls are becoming increasingly popular in the RV industry due to their superior strength and insulation properties. This type of wall construction consists of two or more materials combined together to create an effective and durable solution. This includes a combination of steel, aluminum, foam core, laminated composites, wood or fiberglass materials designed to offer superior protection against the elements while providing sufficient insulation for comfortable temperatures inside the RV. Hybrid walls are often chosen by those seeking higher-end RV wall construction that offers a longer lifespan over more traditional options.

Wooden Frame With Fiberglass Exterior

Wooden frame with fiberglass exterior is another popular choice for RV wall construction. This type of construction consists of a sturdy wooden frame with a layer of reinforced fiberglass on the outside. The combination of wood and fiberglass provides enhanced durability, insulation, and protection from UV exposure and other environmental conditions. Furthermore, it also offers superior soundproofing properties to keep the interior quiet and comfortable. This type of construction is ideal for those seeking a long-lasting, cost-effective solution to enjoy their travels in comfort and style [1].

Some facts about common RV Exterior Walls’ thickness

RV walls’ thickness is critical for their durability and longevity. RV exterior walls are typically constructed with a mix of aluminum or fiberglass sheeting, foam insulation, thin plywood, and luan.

The average thickness of an RV wall varies from model to model but can range between 1-1/2″ to 3-1/2″ with an average of 2-1/2″. Thicker walls provide more insulation, sound dampening, and protection from the elements.

Aluminum RVs are another popular choice due to their lightweight yet sturdy construction. They tend to be more affordable than fiberglass models but may require more frequent maintenance due to corrosion. Aluminum RV walls typically have an average thickness of 1-1/4”.

No matter what type of RV you choose, its exterior walls are an important part of overall construction and should be considered carefully. Thicker walls may provide more insulation, sound dampening, and protection from the elements but will add additional weight to your vehicle. Be sure to research different materials and weights when shopping for your next RV.

Another consideration when choosing an RV is the type of insulation used in its walls. Foam insulation can help to keep your RV warmer in colder climates and cooler in hotter temperatures. This type of insulation also helps reduce noise and dampen road vibrations, making for a more comfortable ride. The best insulated RVs use closed-cell spray foam which has an R-value of between 7 and 10. Closed-cell spray foam has superior air sealing properties which help to keep your RV at a comfortable temperature all year round [2].

RV Walls Versus Residential Construction

How Strong Are They?

RV walls are not as strong or durable as residential walls due to their construction materials, thinner wall thickness, and less insulation. RV walls are constructed with aluminum sheeting, thin plywood, luan, and foam insulation which makes them much lighter than a standard home’s walls.

The average RV wall thickness is only about 2-1/2” thick compared to residential walls which are typically 4-6” thick. However, this can vary between different RV models and manufacturers.

RV walls may be lighter and thinner than residential walls but they are still strong enough to withstand most road conditions and typical wear and tear. Additionally, the use of foam insulation helps keep your RV cooler in hot climates and warmer in colder climates.

Is There a Vapor Barrier?

Most RVs are equipped with a highly effective vapor barrier that is thoughtfully installed within their walls. This crucial layer consists of durable vinyl or plastic sheeting, meticulously designed to combat excess humidity and prevent unwanted air infiltration from the surrounding environment. By acting as a formidable shield, this barrier not only maintains a comfortable interior climate but also ensures that pesky odors and harmful pollutants are kept at bay. It’s important to note that RV vapor barriers are typically incorporated during the manufacturing process, although they can be added later if necessary, providing an added layer of versatility and peace of mind for RV enthusiasts.

Durability and Longevity

RV walls are typically not as durable or long-lasting as residential walls due to their lighter construction materials. However, the use of foam insulation helps protect against extreme temperatures, moisture, and potential road hazards.

It is important to inspect your RV walls for any damage or wear and tear regularly. If you notice any issues, it is important to address them immediately to ensure that your RV walls remain strong and durable for years to come. Additionally, it’s a good idea to have your RV serviced every few years by a certified mechanic in order to catch any potential problems before they become serious.

What About the Mechanical Systems?

In addition to the walls of your RV, it is important to consider the mechanical systems that keep them running. This includes regular maintenance and repairs for your heating/cooling system, plumbing, and electrical components. By keeping up with routine maintenance and repair services, you can ensure that your RV remains in good condition for years to come.

Regularly inspecting your RV’s mechanical systems is an important part of keeping it in good condition. This includes checking for signs of wear and tear, rust, corrosion, or other damage. Additionally, it’s a good idea to have your RV serviced by a certified mechanic every few years to catch any potential problems before they become serious.

Maintaining your RV’s exterior walls and mechanical systems is an important step in ensuring its longevity and keeping it in good condition for years to come. It’s a good idea to routinely inspect, maintain, and repair any issues that arise to ensure that your RV remains safe and performs at its best.

Are RV Walls Easy to Replace?

Unfortunately, replacing RV walls is not always a simple task. Depending on the age of your RV and its specific make and model, replacement parts may not be readily available or easy to find. Additionally, you will need specialized tools and knowledge in order to safely install new panels in place of the old ones.

If you are considering replacing any of your RV’s walls, it is important to consult with a qualified technician or mechanic first. They can help you determine the best course of action and provide assistance throughout the process. Additionally, they can ensure that the job is done safely and correctly so that your RV remains safe and functional for years to come.

Why Do RV Walls Delaminate?

RV walls can be prone to delamination, which is the separation of two or more layers of materials that are bonded together. Delamination can occur due to water intrusion between the layers, poor installation techniques and improper glue application between the layers. The wall thickness plays an important role in preventing delamination from happening in your RV walls.

There are a variety of wall thicknesses available for recreational vehicles, including standard aluminum shell walls, luan interior panels and laminated fiberglass walls. Depending on the type of RV you’re considering, it’s important to know how thick the walls are in order to make sure that your RV will be able to withstand long-term use.

When shopping for an RV, it is important to consider the wall thickness carefully as thicker walls can help prevent delamination and give you peace of mind knowing your RV is built to last. The wall thickness will also affect insulation, so it’s important to consider the R-value of the walls when shopping for an RV as well.

It may seem like a small detail, but wall thickness plays an important role in ensuring that your RV can withstand the elements and last for many years. Taking this important factor into consideration can help you make an informed decision when shopping for your RV.

FAQ

How thick are the walls on an RV?

RV walls usually range in thickness from 1/8 to 1/2 inch. The type of material used also plays a role, with laminated panels being the most common in RVs, ranging from 5/8 inches (for lighter-weight models) to 1 3/4 inches (for heavier-duty vehicles). Foam insulation can also be added for further protection from the elements. It is important to pay attention to the wall thickness of an RV, especially if you plan to travel in colder climates, as thicker walls can help reduce heat loss. Additionally, higher-quality RVs may also have reinforced sidewalls and roofs for added durability. By choosing an RV with thicker walls, you can ensure that your vehicle is better equipped to handle the rigors of the road.

What are the benefits of thicker RV walls?

Thicker RV walls provide several advantages, including increased insulation, improved durability, and better soundproofing. The thicker walls help keep out the cold in winter months and minimize heat loss from the interior of the vehicle. In addition, thicker walls can reduce noise from the road and other sources, making it easier to relax while on an RV trip. Additionally, because thicker walls are more resistant to damage from impact and wind, you can be sure your vehicle will stay in good shape after a long journey.

Are there drawbacks to thicker RV walls?

Although thick RV walls have many advantages, they can also be more difficult to work with. For instance, heavier materials such as steel may require special tools and experienced technicians for installation. Additionally, thicker walls can add considerable weight to the RV, making it more difficult to tow or maneuver in tight spaces. Before deciding on an RV model with thick walls, consider your needs and whether you are willing to sacrifice some of the convenience features in exchange for added durability and insulation.

What is the wall thickness of an RV?

The wall thickness of an RV depends on the type and quality of material used. Laminated panels are typically between 5/8 inches (lightweight models) to 1 3/4 inches (heavier-duty vehicles). Foam insulation can also be added for more protection from the elements, with thicknesses ranging from 1/2 inch to 2 inches. Ultimately, it is important to evaluate the wall thickness of an RV before purchasing, as thicker walls can help improve insulation and durability.

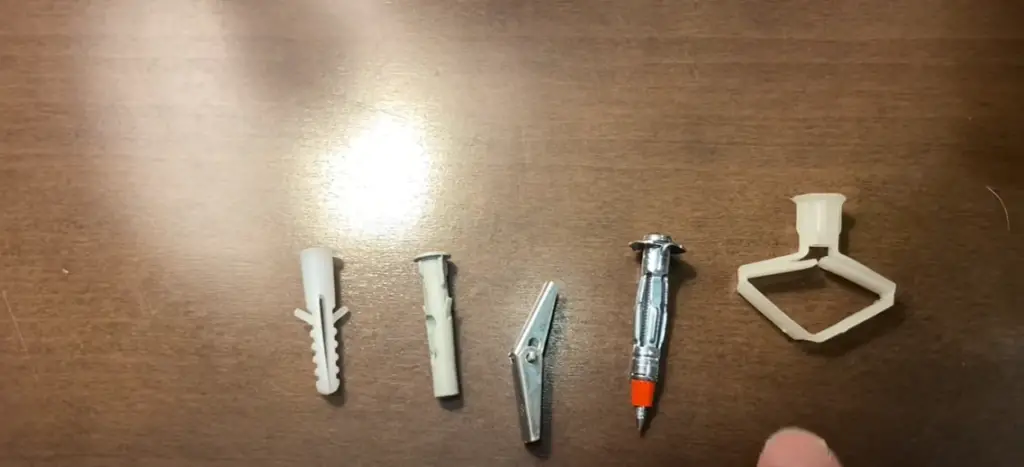

Useful Video: How to Properly Hang & Secure Items to Your RV Walls

Conclusion Paragraph

The thickness of the RV exterior walls is an important factor to consider when shopping for a recreational vehicle. Thinner walls can save money, but they may not be as durable or provide the same level of insulation. On the other hand, thicker walls are more expensive but will last longer and offer greater protection from extreme temperatures. Ultimately, it is up to each consumer to decide what trade-offs they are willing to make when selecting the thickness of their RV wall.

References:

- https://www.getawaycouple.com/rv-wall-construction/

- https://www.rvcampgear.com/how-thick-is-a-travel-trailer-exterior-wall/

Leave a Reply